FAQs on Acrylic Aquarium

Repair and Modifications:

Leaks, Deficient Seams

Related Articles: Aquarium Repair,Related FAQs: Acrylic Repair 1, Acrylic Repair 2, & FAQs on

Acrylic: Design, Scratches & Crazing, Drilling/Cutting, Construction, Solvents, & Glass

Aquarium

Repair, &

DIY Gear 1, DIY

Gear 2, Tanks, Stands, Covers,

Custom Aquariums, Stands,

Covers...,

|

|

|

Acrylic Repair 4/19/20

Good morning,

<Anthony>

I wanted to reach out and thank your whole crew for helping organize a lot

of great information on this site!

<Ahh! Thank you for your kind, encouraging words>

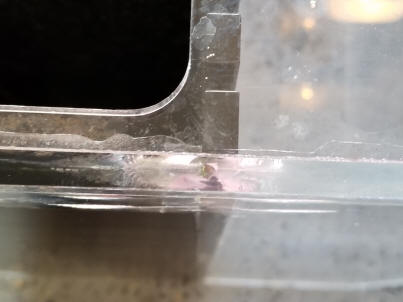

I recently purchased a used 1200 gallon 10x4x4 with 1.25” acrylic walls.

<Mmm; I'd rather 1.5" material...>

It was on a horribly uneven and rusty stand,

<Yikes>

but still holding water, and I’m worried about this one seam on the tank

along the top center wall.

<I see this "white out" area in your pic>

All the other seams hardly have a single bubble, and it’s on a new level

stand. Can I just use Weldon to strengthen this top seam if all the other

seams are near perfect?

<This is what I would try... tilting the tank so the open slit of the seam

is facing upright, putting some sturdy tape along the panels to disallow the

wandering of the low viscosity Weldon, saturating the gap, allowing the

solvent to fill this area... waiting a day to see if this has helped

sufficiently>

Thanks in advance,

Anthony

<Certainly welcome. Bob Fenner>

|

.jpeg) |

|

Re: Acrylic Repair 4/20/20

Thank you very much, I will try my best! Tilting this tank is a whole

project in itself.

<Mmm; thought about this; yeah. Tilting up a ten foot high tank... Maybe

just on the edge will do; be better than just vertical>

Would you recommend Weldon 16 with a high gauge needle for this? Thanks

again, Anthony

<Yes to the #16 and small gauge needle. It REALLY flows into small gaps. Bob

Fenner>

|

|

Acrylic Repair 3/17/20

Hello, I was gifted a 55 gallon Clarity Plus tank (Score!!). The top right

end seal between the arrows on the picture is completely gone (can sand

between the sheets) and possible stress marks in other seams. After reading

through a bunch of your information, I plan on getting some 3/8" square rods

(the tank is 1/4") and solvent them into the entire inside.

My question is whether or not to use Weld-On 3 on the separated top piece

first or not, especially since it goes completely around one corner?

<Likely a good idea... to use a more viscous product. Less viscous/gooey on

the doweling>

Also, how does one reinforce the curved front corners?

<I would leave these as is. This tank should give you good service once the

other repairs are done>

From the pictures, is there anything else I should be aware of? Thank you so

much for your time and expertise.

<Mmm; nothing more. If this were my tank, and I intended to use it long

term, I would proceed as you have detailed. Bob Fenner>

|

|

|

Re: Acrylic Repair 3/17/20

Awesome! I was planning on using Weld-On 16 for the dowelling.

<Yes; this would be my choice>

Should I clamp it in place first and let it seep in?

<Better to just use tape, if deemed necessary; will allow easier flow>

Or put it on first and place the dowels on afterwards?

<Mmm, no, put the cut/sized dowel piece in, one at a time, tilting the tank

letting gravity help with the placement, then use a thin-tipped application

bottle to have capillary action fill the gap. Takes very little material>

I was trying to find that answer on your website, but not running into it...

<I should get off my duff and make a YouTube presentation, or find one and

link it re. Do ask about at your local fish store, aquarium club... plastic

outlet/fabricator to see if someone who has done this work will show you in

person.>

Thanks again,

Julie

<Welcome. BobF>

|

|

Hello Question about acrylic crazing or seam failure

12/7/19

I Bought this tank used. After getting it home noticed these scratches.

<Crazing>

I read your article but don't know how to differentiate between crazing and

seem a failure.

<Seam failure is between annealed/solvented surfaces, crazing stress

fracturing outside the joint>

The tank is not leaking and holds water. Can you shed some light before I

stock this tank.

Thank you,

*Utsav Khatiwada*

<I'd likely still use this tank; assuring its on a stand that is planar,

level (and strong of course). The seams appear strong (enough), just a bit

unsightly. Bob Fenner>

|

Re: Hello Question about acrylic crazing or seam failure.

12/8/19

Yes the stand is very sturdy and the tank has a built in cushion at ye

bottom. It’s for my WC Frontosa Mpembew colony so wanted your expert

opinion.

<Ahh, I too raise frontosa, but not from this locality>

Thanks and I will use this tank until any issue. Thanks

<Certainly welcome, BobF>

Re: Hello Question about acrylic crazing or seam

failure. 12/13/19

Hello there,

<Greetings Utsav>

First I would like to thank you for sharing the information with me. It has been

a blessing.

Do you recommend to seal all the tank with Weldon just to be on the safe side?

If yes, what kind of Weldon should I use?

<I would not randomly apply this solvent... ONLY where the joint is whited

out...

The #16 of Weldon or equivalent is my choice in terms of low viscosity; ability

to seep into the joint. You may need to flip the tank over so the solvent can

more easily soak into the space. IF there's a concern for leaking, DO read on

WWM re installing triangular or quarter stock in all seams>

The tank is dry and hasn't been operational, so I was thinking of taking care of

the maintenance before I pour water in it.

<Good>

Thank you,

*Utsav Khatiwada*

<Welcome. Bob Fenner>

|

|

Aquarium repair 12/6/19

I have a 180 gallon acrylic tank 72x24x24 the tank is empty and it has maybe a

seam separation not sure what it is her is a picture of it any help Thanks

<Hi, could you please resize/crop the image down to just a few hundred Kb's and

resend it? Wil.>

|

|

|

Aquarium repair 12/7/19

I have a 180 gallon acrylic tank 72x24x24 the tank is empty and it has maybe

a seam separation not sure what it is her is a picture of it any help Thanks

<Mmm; you may be fortunate here to be able to simply apply a low viscosity

solvent (Weld-on 16 would be my choice) to the seam/area here this is whited

out. Elsewise, annealing a square or triangular dowel in the inside corner

(the entire length, if it were mine, all inside corners), cut to size, as

gone over on WWM re acrylic repairs. Bob Fenner>

Re: Aquarium repair 12/7/19

So I should apply Weld-on 16 from the top to the bottom seam and add a

acrylic piece as well top to bottom

<Mmm... the solvent just to the joint (bottom) where the whited out area is

what I would try first. Give it a couple days to cure. BobF>

|

|

Acrylic Tank seam crazing... 8/29/19

Hello, My name is Mike and I have a question about my 280 gallon 72x28x24

acrylic tank. On the front panel of my tank both side seams are starting to look

like the photos below... Should I be concerned and is there a way to fix and or

prevent from getting worse?

Thanks, Mike

<Hey Mike, could you please resize your pix to only a few hundred KB's and

resend them ? Other wise you may crash our server. Wil.>

Acrylic Tank seam crazing... 8/29/19

Hello, My name is Mike and I have a question about my 280 gallon 72x28x24

acrylic tank. On the front panel of my tank both side seams are starting to look

like the photos below... Should I be concerned and is there a way to fix and or

prevent from getting worse?

Thanks, Mike

<Is the front panel bowed?...apparently the water pressure has weakened the

seam/seal and it may worsen in time, unfortunately the route to go is to drain

the tank and get some skilled, experienced person to reinforce it, please see

the following link and above.

http://wetwebmedia.com/acrylictkreprfaq2.htm Cheers. Wil.>

|

|

|

Re: Acrylic Tank seam crazing... 8/29/19

The front panel is slightly bowed, maybe a 1/8"... I was afraid some

reinforcement was probably going to be needed luckily I am fairly skilled at

working with / welding acrylic.

<Great that you are skilled Mike! Good luck with the repair.>

Thanks for your help!

<You’re welcome. Wil.>

|

|

Failed Seam? 6/4/19

Hey guys.

<Hey Cody>

I have a 250 gallon L shaped TRUVU aquarium that I purchased second-hand. I

noticed that all of the seams kind of look like this. Lines throughout the seams

and hazy looking. Are the seams failing or is this

normal?

<It is not normal; water pressure has weakened the joints. I advise you to

reseal all the seams with a low viscosity Weld-On product... a professional or

skilled person may do this for you.>

Thank you SO much for any advice,

Cody

<You´re welcome. Wil.>

|

|

|

acrylic crazing 5/14/19

Is this fix able? What # Weldon would I use and how? Thanks so much

<Mmm; not crazing... but a failure in the seam/seal itself.

The choice up to you, but I'd likely solvent a (two inch or so acrylic) strip

along the side (edge where the two pieces meet)... akin to glass/Silicone

aquariums where the seal is (badly) compromised). I would

NOT add Weldon or other product to the existing seam as this may simply weaken

the current bond. Bob Fenner>

|

.jpeg)

|

Potential disaster?

9/2/18

Hello Experts!.

I set up my old 240 (well over 30 years old) that had been dry for years. I

noticed 2 months later now that the lower right corner seem has turned white for

about 6".

<Yikes>

The Aquarium- A Tru-vu has survived Earthquakes and bad leveling before over the

decades...moved and dried for long stretches too.

Since its full of (80 pounds of pool sand) sands ,fish, water plants. Is there

anyway to inject a glue into a seem underwater..that still has no gap?

<No there is not. Do NOT use acrylic glue... it's not glue, they're solvents!

Will loosen the gap here. The system HAS to be drained/emptied, completely

dried... AND THEN I would solvent a square/dowel along the entire seam. In fact

I'd go ahead and do ALL the inside seams while you're at this. DO take care to

inspect the doweling, as it is often only square/flat on two sides (of the

four); you WANT these two flat sides at the seams>

Is there any miracle cure?

<None that I'm aware of>

Its survived a lot. I did put even more bracing under that corner..hoping to

remove anymore stress.

What are the odds..it just stays the same another decade or so?

<Not good enough for my peace of mind. I sold hundreds of Tru-Vu Aquaplex tanks

over the years. Very good products; thirty years of service is exemplary>

AS long as I'm asking..if it ever leaks? is it possible for average guy me to

fix it - by then dry of course.

<Yes it is; as briefly gone over above and over and over archived on WWM>

I only thank god I used and had all the hardware to start. I only have bought

about $150 worth of fish and plants. From the gitgo I wanted a budget big

freshwater setup.

So, If it should give out..I still don't want to give up on the thing.

BUT!!,right now, any IN TANK repairs that would help? Asking a lot..but

something must have been invented for non toxic in tanks glues!.. I hope!

<No in-tank ones unfortunately. IF this were a MUCH larger system... we might

discuss making a chamber to fit the corner inside to work in dry...

Bob Fenner>

thanks!

Stan.

Re: Potential disaster? 9/2/18

Thanks for the reality check.. All I can do is see if its stopped in its tracks

with more bracing.

<We did these fixes all the time... esp. important in CA where the ground shakes

at times. Weld-On 16 does a good job viscosity wise for both the in-fill and the

new bracing>

I know that if it gives..I will fix it. Only when its dry this time..I redo that

whole tank and buff the heck out of it. 35 years of algae scraping scratches

means its also not the clearest sheet of Acrylic on the

block.

<Ah yes>

Somebody else said that fixing a de-seamed Acrylic is easier then glass...you

don't remove the Acrylic panes. you just fill in the gap and by the next day you

COULD fill it with water. I hope!

<Mmm; well; both are a pain. Just today resealed (over) a Juwel/Eheim four foot

tank...>

I appreciate your help, believe me!

Stan.

<Oh yes; I can indeed imagine. Cheers Stan. BobF>

Re: Potential disaster? Acrylic seam repair cont.

9/3/18

One more question, I have to ask- Would it help top apply weld 40 or even super

glue to the outside seems length?

<... no; don't do this>

Stop it in its tracks? Prevent further travel?..

<No Ad... again, acrylic solvents are just that. They'll open the gap if the

seam is under pressure>

I found a months ago photo of that tank-and it was already liked that.

After 35 years, I stopped noticing things I guess.

THANKS!

<Welcome. B>

|

Acrylic Aquarium Question- help

10/25/27

Hello-

<Howsit?>

I’ve been reading your forum on Acrylic seams, cracks, etc and wanted to ask Bob

Fenner a question. I can’t see where to post a question and was wondering how to

reach him? I just built my first aquarium, it’s 300 gallons and I have some

concerns about the seams that I wanted to ask him. Can you advise where to ask?

<This is it mate. Please ask away. Bob Fenner>

Thank you!

David

Re: Acrylic Aquarium Question- help 10/25/27

Hey Bob! So, like I said I just finished my first build, of a 300G acrylic for

my home. It’s 1” acrylic on all sides and 1/2” on the top and bottom.

<? I encourage folks to have tops, bottoms of acrylic tanks at least the

thickness of the rest... thicker if the tank is tall>

It will be set on top of a solid wood stand with a 2” thick concrete countertop.

Dimensions are 72x24x30. Everything was cut with CNC machine and all the pieces

are square/plumb, etc.

<Good>

All my sides came together perfectly and my top went on perfectly... my only

concerns are with the bottom piece. I did the bottom last, and with all the

weight (even using the pins method) the weld-on #4 didn’t create solid clear

joints like everywhere else. There were like 5-6 spots total around the whole

base where it created pockets that sealed and I just couldn’t wick it in there.

Doing this over, I think I would’ve used the 2-part epoxy, but overall the

solvent did really well considering it’s 1” thick acrylic. So, all things

considered I’m happy that the joint pockets happened on the bottom piece rather

than the corners or the top (I think?) take a look at the attached pics and let

me know your thoughts. Would a catastrophic failure be possible if only the

bottom seams are like this, since it’s fully supported underneath? Like I said,

90% of the bottom piece is good, but there are several pockets that are there.

Thank you for your help!

David

Ps. After reading all the forums, I realize I could have added doweling if need

be, but I already added a thick bead of #16 around all the bottom seams for

extra support. I filled the tank twice and let it sit for a couple days and had

no leaks, no movement, no cracks or hazing, etc.

<Mmm; okay... IF there is further concern (or reason for concern!), I would add

the doweling all around the inside bottom. Bob Fenner>

|

|

|

Re: Acrylic Aquarium Question- help

10/26/17

Hi Bob-

<Hey David>

Is there reason for concern after seeing the pics of the bottom joints?

<Mmm; not much; no. I would have stated (shouted) emphatically if so>

If there were to be a failure, what do you think the signs would be if this

is only the bottom piece?

<Whiting out of the joint, with the creeping whiteness extending the entire

width of the joint... DANGER>

Is the bottom piece the least stressed since it’s got full concrete support

underneath?

<Not the least... this would likely be the top. It's not too late to anneal

another panel to both top and bottom if you're concerned>

How would I place the doweling (if needed) if I already put a thick bead of

#16 around all the inside bottom joints?

<Mmm; you're not going to like this; but gingerly using a tool to chip,

grind out the material that would be in the way of the dowel.

Another/alternative would be to affix another bottom all the way around,

enclosing the present one and a small area of the viewing panels. This is

often done with large, very large circular acrylic fiberglass tanks. Where

to send you for further input.... oh, for sure:

http://www.waterdogproducts.com/

Bob Fenner>

|

|

90 gallon reef tank... cracks. Crazing?

10/17/17

I have a used 90 gallon reef tank with these cracks at the top of the

tank at the overflow. The overflow is on the side. You can't

feel them from the inside or outside. Or these fixable or is my tank

done and should be

trashed

<.... I take it this system is acrylic... Need to see well-resolved images of

the "bad areas" to give much of a solid opinion. Please read here:

http://www.wetwebmedia.com/acraqleaks.htm

and the linked files (above, in blue), and send along the images when you can.

Bob Fenner>

re: 90 gallon reef tank 10/18/17

These are the best I can get.

<.... wouldn't worry re these. IF/when the system is empty, dry, perhaps some

Weld-On 4 as gone over on WWM. BobF>

|

|

|

re: 90 gallon reef tank 10/18/17

So this tank is ok to use as my main tank?

<Yes>

Also if we're get some weld on 4 how would I get it into the cracks since they

are not open to the tank inside or out?

<Only at the seams. B>

re: 90 gallon reef tank 10/18/17

Ok you are awesome thank you so much

<Welcome. B>

|

Acrylic Aquarium Seam Failing ...Did I make it worse?

10/10/17

Thank You all for the FAQs on acrylic aquarium repair.

<Welcome Chris. Am very glad to have accumulated these>

Your site is sure to become a valuable resource for me. I have a used

325 gallon 2mX80cmx80cm acrylic tank. Some of the corner seams have the

white crescents and other irregularities which look exactly like those

on the

photos on your site at:

http://www.wetwebmedia.com/acraqleaks.htm

FAQs on Acrylic Aquarium Repair and Modifications: Leaks

...<http://www.wetwebmedia.com/acraqleaks.htm>

www.wetwebmedia.com

Acrylic Aquarium Repair 4/15/17 Hello there and thanks for providing

such an informative website! I purchased a used acrylic tank whose

condition is a bit rough, it ...

I had outlined some of the crescents in marker when I set up the tank in

Dec 2015, and noticed yesterday that many had grown considerably

and are approaching the interior edge of the seam.

<No bueno>

So I drained the tank about 60% and used a locally-available

water-thin plastic solvent in the white areas of the seams (dripped in

with a needle applicator) .

<... while the tank had water in it? Yeeikes... the solvent could melt

the existing bond!>

I could see the solvent quickly spread by capillary action, but the

areas remained white.

<Yes... may be too "whited out" to make a clean joint again...

NEED to empty, dry... apply the most viscous Weldon (or equivalent) you

can get, tape over the applied areas to give the solvent time to work>

Oh By The Way...I live in Japan. So none of the labeling on the solvent

that I used is in roman letters, so I cannot tell exactly what chemical

it is.

I am going to try and obtain some Weldon 4. But first I have some

questions:

1. Must the white areas turn clear to be fixed?

<Mmm; no... but the "clearer they are", the more fixed>

2. Have I maybe applied a barrier to the Weld-on 4 being able to make a

bond?

<Ahh, yes!>

3. Is Plexiglas similar enough to tank acrylic to test adhesives? IE if

it works or does not work on Plexiglas, will it work or not work on

acrylic?

<The terms acrylic and Plexiglas (both PMMAs) are often used

interchangeably. Solvents, tools, methods for one should work on the

other.

http://akriform.se/en/news/plastic-acrylic-and-plexiglass-we-explain-the-difference/>

Thanks in advance for any advice,

--Chris

<Welcome. Bob Fenner, who WOULD re-read what we have on WWM, and LIKELY

install the square Plexi doweling as gone over here>

Re: Acrylic Aquarium Seam Failing ...Did I make it worse?

10/11/17

Many Thanks Bob

<As many welcomes Chris>

Oh yes, if/when I am ever obliged to move, I'll definitely have that

square doweling installed in all the corners before setting up the tank

again.

(And have a cement-floored fish room with a drain, ha!)

<And a built-in cabana bar!>

I did draw down the water level to below where the 'white area' seam

failures are occurring.

<Good>

You have started me on doing my own research, but in the meantime;

By "most viscous" Weldon product, is there a specific one that you

recommend? Is it also applied with the needle applicator?

<The number four is best here: You can buy it from Amazon and use it

with the needle applicator:

https://www.amazon.com/Weld-Acrylic-Adhesive-Applicator-Bottle/dp/B0096TWKCW

--Chris

<BobF>

Re: Acrylic Aquarium Seam Failing ...Did I make it worse?

10/13/17

Thanks Again Bob

Now I need to pass-on the good karma this week ��

<Ahh. B>

--Chris

|

Large Acrylic Tank; joints whiting out, crack...

6/22/17

Dear WWM,

<Casey>

I would be very grateful if you could give me some advice.

<Glad to>

I recently acquired a 700 gallon acrylic aquarium. I thought it was a

real steal for $500.

<Tis; for the acrylic alone...>

The aquarium has an area about 8 inches long at one of the seams that

appears to have been damaged judging by the visible hazing in this location.

<Yes; the weld/joint is going bad...>

There are two visible cracks on either end of this area that

may have occurred when moving the tank into my house (I'm not sure if they were

there before, the hazy area was there before, but I had not noticed the cracks

before the move).

<Mmm; more likely from before... when the tank was full. These cracks are most

often due to uneven pressure when the tank is filled, setting on an uneven

(non-planar or not level) surface/stand. Even more common in specialty tanks

(not rectangular or square on the bottom). Stands for such often have such

non-planar, non level issues. Read here:

http://www.wetwebmedia.com/aqstands.htm>

The cracks do not extend completely through the acrylic sheets so I don't think

leaking will be an issue,

<Umm; no. DO NOT FILL this tank w/o correcting these. VERY dangerous should this

tank fail catastrophically; with it MAY DO>

but I'd like to do anything possible to prevent that the cracks from growing and

become a problem. What would be the best way to repair or mitigate this damage?

<... some folks (we used to fabricate) might try applying a low viscosity

solvent... e.g. Weld-On 16 to the joints, cracks, in the hope of "filling them

in", re-joining the areas. I would NOT DO THIS, but instead have a professional

shop cut and install acrylic doweling of at least one inch diameter in all

linear seams inside. Read here:

http://www.wetwebmedia.com/acraqleaks.htm>

My current plan is to try and repair the seam by injecting IPS-4 acrylic solvent

into it using a syringe with a small gauge needle and applying light pressure

with a bar clamp.

<No need for a clamp>

I've also ordered some 3/4" acrylic right triangle rod to solvent weld into the

interior corner to reinforce the entire seam from top to bottom.

<Yes to this, but I'd make it a minimum of 1">

I'd be grateful for any advice you have as to these plans or any better course

of action. One particular question I have is what would be the best method for

welding the triangle rod reinforcement into the interior corner?

<Carefully measure, cut, practice fitting in all pieces, apply braces to keep

added pieces in position, use capillation to fill in the voids. IF all is cut

and placed properly, the solvent will fill the gaps>

Is there a particular type of solvent or method for applying it that you

recommend since the piece has to go in vertical?

<... Yes; the Weld-On line>

Would capillary action work or would it be better to try and find a more viscous

solvent that could be applied before putting the triangle rod in place?

<Capillary action will do>

What would be a more viscous product that I could use? Would IPS-40 be

appropriate here?

<For me, the lower viscosity>

Is there any other actions I could take to repair or reinforce the tank?

<Yes; to MAKE SURE the stand is LEVEL AND PLANAR; DO the repairs, bracing work

ON THE STAND if practical>

Any advice you have would be very much appreciated!

Thanks,

Casey Alexander

<Unless you're very handy (whatever this is... good mechanical skills, vision...

I no longer have), I'd seek experienced help w/ this repair. Bob Fenner>

|

|

|

Re: Fwd: 6/22/17

Bob Fenner,

<Casey A>

Very grateful for your reply and advice. I'll let you know how it goes.

<Ah, thank you. Bob Fenner>

Thanks

|

Re: Acrylic seam repair 7/5/17

Bob,

<Casey>

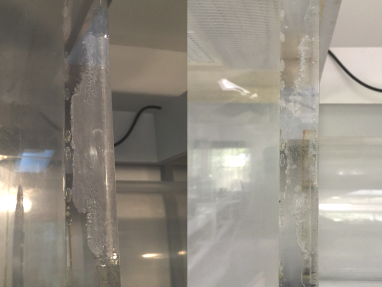

I’ve started repairing the damaged seam on my acrylic aquarium. I was able to

inject solvent into the damaged area fairly successfully using a 31 gauge

insulin needle (see attached picture). The white hazy area where the seam was

coming apart has now been reduced by 80-90%.

<Looks MUCH better, yes>

I had also ordered some triangular acrylic rod for doweling the interior corner.

When the material arrived, I believe due to it being extruded, the sides were

not perfectly flat and it did not fit tightly into the corner.

<Do turn it... two sides SHOULD be flat; square doweling is>

I tried machining the sides flat using a router table. I used some of it on one

of the back corners of the tank (that won’t be very visible) as a test. I was

able to get decent adhesion, but not perfect and certainly not a totally clear

weld. Would this likely have come from an imperfect fit?

<Yes; easily. Sometimes using a thicker solvent will/can fill in these non-flush

areas better>

You recommended using square rod for the reinforcement. Can you recommend a good

supplier with rod that is good and flat on the sides?

<Mmm; I cannot... outside of where I live (San Diego, S. Ca.) I don't know...

the brand names for such. You might call ePlastics re: (858) 560-1551>

Also, I was wondering if painter’s tape can be used to protect the nearby areas

from solvent drips?

<Sorry; I don't know this either; but worth trying... perhaps laying some other

sticky plastic tape on top of the painter's tape in turn?>

Thanks,

Casey

<Welcome. Bob Fenner>

|

|

|

|

Acrylic Aquarium Repair 4/15/17

Hello there and thanks for providing such an informative website! I purchased a

used acrylic tank whose condition is a bit rough, it’s 150 gallons 72”x24”x20”

3/8ths thick sheet pretty standard stuff. Anyhow I could really use an expert

opinion on whether this tank will require dowelling after I re-solvent the

separated chemical welds.

<Yes; I would apply doweling here. My rule of thumb is anytime, with the whiting

out anywhere, that more than half the joint is troubling... to do so. Plus the

nearby crazing worries me.>

If so must I use cast acrylic or can an extruded rod be utilized for the

dowelling?

<Either will be fine here; for this application.>

Furthermore when do you recommend using weld-on 3 versus weld-on 4 for

re-solventing?

<Both are close to being about the same viscosity. I like "runnier" for tight

areas, brand new material in general>

The enclosed photo is of the front upper left corner, and is by far the worst

corner of the aquarium the rest of the tank is surprisingly not so bad. Thanks

for providing information that allows a regular working guy to afford his dream

aquarium! Thanks David

<Welcome! Bob Fenner>

|

|

|

Re: Acrylic Aquarium Repair 4/16/17

Hi Bob thanks for getting back to me so fast, in your response about

dowelling the corners you mentioned the near by crazing worried you

how so?

<Evidence of stress there... could be from poor matching of joints, uneven

stand, weak acrylic.... But points to the need to add the doweling>

With the additional dowelling should I worry about the crazing?

<Less so>

I thought it was minor you can't feel it at all, but then again I’m no

expert. Thanks

<Welcome. BobF>

Re: Acrylic Aquarium Repair

4/17/17

Got it, I will weld up a steel stand with a 1 ½ butcher block top to support the

tank properly; dowel all internal corners, and re-solvent the bad seams. Thanks

for the sound advice!

<Very glad to share. Bob Fenner>

Acrylic Aquarium Seam Failing ...Did I make it worse?

10/10/17

Thank You all for the FAQs on acrylic aquarium repair.

<Welcome Chris. Am very glad to have accumulated these>

Your site is sure to become a valuable resource for me. I have a used 325 gallon

2mX80cmx80cm acrylic tank. Some of the corner seams have the white crescents and

other irregularities which look exactly like those on the

photos on your site at:

http://www.wetwebmedia.com/acraqleaks.htm

FAQs on Acrylic Aquarium Repair and Modifications: Leaks

...<http://www.wetwebmedia.com/acraqleaks.htm>

www.wetwebmedia.com

Acrylic Aquarium Repair 4/15/17 Hello there and thanks for providing such an

informative website! I purchased a used acrylic tank whose condition is a bit

rough, it ...

I had outlined some of the crescents in marker when I set up the tank in Dec

2015, and noticed yesterday that many had grown considerably and are

approaching the interior edge of the seam.

<No bueno>

So I drained the tank about 60% and used a locally-available water-thin

plastic solvent in the white areas of the seams (dripped in with a needle

applicator) .

<... while the tank had water in it? Yeeikes... the solvent could melt the

existing bond!>

I could see the solvent quickly spread by capillary action, but the areas

remained white.

<Yes... may be too "whited out" to make a clean joint again... NEED to

empty, dry... apply the most viscous Weldon (or equivalent) you can get, tape

over the applied areas to give the solvent time to work>

Oh By The Way...I live in Japan. So none of the labeling on the solvent that I

used is in roman letters, so I cannot tell exactly what chemical it is.

I am going to try and obtain some Weldon 4. But first I have some questions:

1. Must the white areas turn clear to be fixed?

<Mmm; no... but the "clearer they are", the more fixed>

2. Have I maybe applied a barrier to the Weld-on 4 being able to make a bond?

<Ahh, yes!>

3. Is Plexiglas similar enough to tank acrylic to test adhesives? IE if it works

or does not work on Plexiglas, will it work or not work on acrylic?

<The terms acrylic and Plexiglas (both PMMAs) are often used interchangeably.

Solvents, tools, methods for one should work on the other.

http://akriform.se/en/news/plastic-acrylic-and-plexiglass-we-explain-the-difference/>

Thanks in advance for any advice,

--Chris

<Welcome. Bob Fenner, who WOULD re-read what we have on WWM, and LIKELY install

the square Plexi doweling as gone over here>

|

Acrylic tank lifespan 3/30/17

Hi, I am rather humbled to ask, but what is the "lifespan" of acrylic

aquariums for both larger and smaller models? I ask because I have been

in the tank maintenance business for 25+ years, and some of my clients

tanks are that old or older.

<A well-made system of small/er size (hundred gallons or so) should last

twenty years or more if kept on a level, planar stand>

Also, if an acrylic tank starts to get the "cloudy spots" in the seams,

or any other tiny leak, will those seam leaks grow?

<They will unfortunately. IF there are whited out areas that approach

half the seam width, a good idea to drain, have corner doweling

solvented in all inside seams>

Thank you in advance

Bill Thomas

AquariumsW

<Welcome. Bob Fenner>

|

140 acrylic aquarium; concern re defects

1/21/16

Hello,

<Howdy!>

So I purchased a 140 gallon Acrylic aquarium off crag list for $400. The

dimensions are 60x18x30, my question is should I worry about these I don't know

what to call it other than anomalies in the panes which I guess is called a

joint. I have never had an Acrylic aquarium so I have no idea but I'm worried

after a little research on how to remove scratches lead to reading about

catastrophic failure .

Thanks Manuel

<The bit of hazing, scratching is not problematical; and the blem in the joint

looks fine from the one pic you sent. Does the "whited out" area extend far into

the joint? (when seen from the direct on view?). If more than a quarter way

through, ahead of filling I would fill w/ a low viscosity Weld-On product as

gone over on WWM.

Otherwise I'd use this tank as is.

Bob Fenner>

|

.JPG)

|

Re: 140 acrylic aquarium... no rdg.

1/22/16

Ok, thanks again for you input it's much appreciated . The whited out area you

speak of do you mean like a blotch spot?

<Yes; these are vacuolations... areas where the solvent is/has failed twixt

panes>

The panes are 5/8" thick

<Plenty thick>

, the guy I bought it from said the blotches are just cosmetic but I have my

doubts.

<Can be more.... you didn't read....>

My only concern is the tank being safe to setup in my living room and not worry

about walking in a small pond one day. I provided one more picture of the right

side of tank.

<One last time (with a twist) HERE:

http://www.wetwebmedia.com/acrsolvents.htm

and the linked files above.... it's like a jingle. BobF>

|

.JPG)

.JPG) |

Re: 140 acrylic aquarium 1/23/16

Got it went over it very helpful.

<Ah, good>

To get a better idea of how this happen , I'm guessing the blem is a result of

the outer seam not bonding or unbonding ?

<Un; yes>

If I use the tank as is, in your opinion will it be fine until I save enough

money to buy a new one with the same dimensions ? About maybe six months to a

year?

<Yes; highly likely; though... as prev. stated, and listed a few times in our

archives. T'were it me/mine, I'd opt instead to "fill" the whited out areas w/

solvent (while the tank is empty)... B>

Thanks again Manuel.

|

|

Acrylic Tank Question; seam going

6/15/15

Hi guys! Thanks for the website and the info--due to some (possibly overly

paranoid) worry I have, I wanted to send you an e-mail about a tank I just got.

Picked the tank up from someone who was looking to get out of fishkeeping, he

had it for several years and never had any issues with leaks and despite being

on a stand that I don't think was the best (large gap in the middle so it wasn't

supporting the entire bottom of the tank, which we would be reinforcing), there

wasn't any bowing going on. I think the brand was SeaClear, unfortunately only

3/8" thick which seems to be pretty standard for these mass produced tanks, and

there is some noticeable crazing with a few spots that made me a little uneasy.

I'm not super familiar with acrylic tanks, but I wanted to send some photos of

the spots I mentioned to see if I'm just being paranoid or if there is serious

cause for concern.

<The whited out area labeled Right Bottom is (too) bothersome... While the tank

is out, clean, empty... I would use a water thin solvent... such as: "SCIGRIP 3

Acrylic Solvent Cement, Low-VOC, Water-thin".... applied with a small squirt

bottle with needle applicator... will take just a drop... into the seam/gap

here>

For as long as he had the tank, there were no issues, no leaks, bowing, or

anything like that and he kept an Oscar, a Parrot, a Firefin, two Plecos, a

number of pretty decent sized rocks/ornaments and a lot of substrate for several

years without any issues. Am I getting worried over nothing?

Thanks

guys!

<All such "bad areas" that go this deep into the seam are definitely worth

worrying about, and fixing. In this case, likely just by re-solventing the

area/s... In more advanced cases by fitting in square doweling (of acrylic;

check that the corner inserts are 90 degree angles; i.e. NOT concave), with

heavier bodied (Weldon 16 my fave) solvent... in all internal corners...

Bob Fenner>

|

|

|

Re: Acrylic Tank Question 6/15/15

Yeah, the impression I was getting from your site and others was that using the

two products you mentioned would help fix the problem, with the latter applying

to tanks that looked worse than ours.

<Yes>

If we just use the Weld-On 3, how long do you think could we reasonably expect

the tank to last without fear of leaks/bursting?

<IF the white out completely disappears, indefinitely>

Thanks so much for the response, Bob :D

Mark Hemmert

<Glad to share. BobF>

Re: Acrylic Tank Question 6/15/15

Is the solvent anything we could buy locally, or is our best bet to order

online?

<You might get lucky and find someone who sells nearby... like an acrylic

fabricator, outlet... Most folks have to order. B>

|

|

Acrylic crazing

5/8/15

Hi, I have a standard 180 gallon marine aquarium, 6 x 2 x 2. Acrylic is 1/2 inch

thick with heavy Eurobracing. The tank has been running for one year.

After hearing about crazing and tank failures

<Mmm; not from crazing; no>

I noted some crazing on my tank mostly on the right seem towards the top. See

picture.

<Oh! This is a seam issue, not crazing really... your MEK joint weld is

partially failing. Still... it doesn't appear to be "that bad">

The tank is finally looking great and I would hate to tear it down, but can't

take the chance on a failure either. Would love an expert opinion. Thanks Mark

http://s266.photobucket.com/user/Medicmark737/media/craz4.jpg.html?sort=3&o=17

<T'were it me/mine, I'd leave as is... IF the white-out areas move to half the

seam however... In the meanwhile, I would send along this pic to the

manufacturer, fabricator for their input. Bob Fenner>

|

|

|

Re: Acrylic crazing 6/9/15

I bought it off CL. It was 6 years old but never setup by the owner, so no info

on manufacture etc.

<Mmm; and I don't recognize the design...>

Thank you for the prompt reply. It really helps.

Mark

<Glad to be of help to you. Again; I would not worry, not take this tank down.

Bob Fenner, whose employee-owned corp. used to do such work>

|

|

Acrylic tank; blem., stand/level concern

12/31/14

I wanted to ask you guys a couple questions. I have a 1200

gallon 1 1/2" acrylic tank. The seems look ok with some

crazing. I have included a pic at the top of the front panel. It is

about 1/2" wide so it is still leaving about an inch of bonded space.

<I see this "blem"... and suggest you or someone try a low viscosity

Weld-On product or equivalent... to fill in this gap>

Should I reinforce this or is this ok if the rest of the tank is normal?

<Because it is near the top, its shape, size, not likely a problem ever;

but I would still try capillating in a wee-bit of solvent here.

Take care NOT to drip excess... perhaps a bit of blue tape around the

area lest there be run-off>

The tank dimensions are 10'x4'x4'. My last question is

I talked to an engineer and my tank is level side to side but

from front to back (4' side) it is almost a 1/2" unlevel.

<?! What?... I really, make that REALLY don't like this... measure the

panels... length and width... is/was one side actually mis-cut this half

inch?>

He said this was about an extra 100lbs on that panel but should be

fairly insignificant to the rest of the tank. He said it should be fine.

Do you agree with this? Thanks.

<"Should be fine" in that the tank should not catastrophically fail,

yes... but if this were some tank our old company had fabricated, we

would not ship it; and if I paid others to make it; I'd at the very

least extract a ten year warranty against leaking or failure... if not

sent it back. Bob Fenner> |

|

|

Re: Acrylic tank

12/31/14

Thanks for the responses. I probably phrased the question wrong. The tank is

all the same size, just my floor has a slight decline causing the tank to

lean slightly.

<Ahh; still a concern. I'd be making sure the floor underneath is strong

enough by far... AND shimming up whatever support you're utilizing to spread

the mass of this set up about, above or below floor>

The tank side to side is level but because the concrete

<Oh! On the floor side then>

is slightly going down hill, the water level is about 1/2" higher in the

front of the tank than the back. So over 4' it has a 1/2" decline. Is this a

problem or was the engineer correct in saying the panel will hold about

100lbs of water extra and shouldn't be a big concern?

<It is FAR better for you to make sure the tank is level AND planar. Have

you read my article re stands on WWM?>

Thank you.

<Welcome. BobF> |

|

A Question about Acrylic Tanks

11/15/14

Hi,

<Ray>

We just has a 150 gal custom acrylic tank fabricated for us. The

one side seam has bubbles trapped in the entire length of the seam,

pictured below.

<... poor technique applying the solvent, filling the gap>

The acrylic material is ¾" so I don't think this is a structural or leak

issue but one of cosmetics. Is this typical of acrylic tanks or

unacceptable?

<Mmm; not typical or desirable... >

The tank cost upwards of $4k.

<Well... likely to "be okay" in terms of the tanks integrity, holding

together... IF only on one seam... I might have the fabricator install a

support in the one/two corners (along the entire run) AND turn the

tank's back to the wall (if being installed against one)>

Thanks you in advance for your opinion.

rsf

<We used to fabricate up to 2"... would not allow such work out of the

shop. Bob Fenner>

|

.jpg)

.jpg) |

|

Re: A Question about Acrylic Tanks 11/15/14

The tank is free standing in the middle of a room. There is some millwork

under and above but out in the open.

Ray Fischer

<Uhhh! I would not then (for appearance-sake) install the corner bracing...

BUT would extract a longer-term (five-ten year) guarantee from whomever

fashioned this tank. Don't know what they used to "off-set" (this statement

for browsers) the panels to be welded, but I would have used small piano

wire sections. Cheers, BobF>

Re: A Question about Acrylic Tanks 11/15/14

Hi Bob F

So your telling me this is acceptable and I should pay for the tank?

<WITH the stated warranty, yes. B>

Thanks,

rsf

Re: A Question about Acrylic Tanks 11/15/14

Thank you very much for your time

Ray Fischer

<Welcome.>

Re: A Question about Acrylic Tanks... seams/solvent

11/17/14

Hi Bob F,

<Hey Ray>

Thank you for your help. The tank fabricator is stepping up to the plate. He

is sending a rep up to correct the problem.

<Please do make known his and your further impressions. BobF>

rsf

|

Internal overflow leak 5/29/13

Hello aquatic experts,

I'm sure this question is answered somewhere on your site but it has

defeated my attempts to find it. I have a built in overflow that has a

small leak at the bottom. The leak is between the overflow and the tank

so no water gets on the floor as long as the power stays on. But since

the leak causes the overflow to equalize with the tank any power outage

will drain the tank about 6 inches, which is more than my sump can

handle.

<Have to get a larger sump (volume) and leave the water level down

there...>

I currently have the pump off, and closed the return valves so this can

not happen but I would like to get my tank connected to the sump again.

Is there a way I can seal this leak without draining the tank?

<A couple of standard approaches... there are epoxies... that can be

applied/reapplied around joints, with or w/o another piece of acrylic (I

take it as the material of construction... there are repairs for glass,

PVC...). All require draining the tank... You may want to consider

inserting an overflow pipe, pushed or threaded (if the

bulkhead/through-put fitting on your tank is threaded)... Raising

it/this to near the height/level of your overflow teeth>

Both the tank and the overflow are acrylic. The

overflow is in the middle if the back wall and goes from the base of the

tank up, with the holes in the bottom.

The leak is somewhere along the bottom edge where the overflow meets the

base but I do not know exactly where.

<Again... likely just thicker, more viscous (less fluid, more molasses

like) Weld-on is the route I'd go>

Thank you for your assistance.

Ej

<Take your time here... planning, containers, friends to help hand out

the gravel and rock... can be done in a few hours time with all tools

and materials on hand... Oh, and DO get the larger and/or additional

sump for transit volume, test (unplug pump/s) to assure it won't

overflow. Bob Fenner>

|

Acrylic tank crazing in seams – 5/22/12

Hello,

<Cindy>

First, thanks for all the useful information your site provides. I

have read the information currently on the site for acrylic tank

crazing/cracking issues. I have a 64"l x 15"w x 24"h Clear for

Life tank which has 3/8" acrylic. Bought it used so I do not know

it's age. It had only very few minor scratches, no cracks, but

some crazing in the seams.

<Mmm, not crazing... but vacuolations... spaces/gaps where the solvent

(during construction) didn't flow to, seal face to face. Happens when

sheets aren't square, and/or not held close (enough) together while

solventing>

I have never had a take this large or an acrylic one. Tested for

water tightness before setting it up and no problems - minimal bowing

when filled. Top brace looks good. I have set the tank up

and the crazing in the seams is concerning me.

There was some in the bottom seams, but very little. My real

concern are the side (vertical) seams along the colored rear acrylic

piece. I have enclosed two pictures of the most affected seam.

I have had the tank set up a couple of months, and although the crazing

does not appear to be growing, but either I did not notice the cloudy

fading horizontal bands layered up the seam (blue to lighter cloudy

blue), or it now has those cloudy bands.

I really need someone else's opinion of whether this is minor or could

cause a failure soon. The hood that is one the tank is very heavy

and I am wondering if this could be an issue?

<Not likely; no. This tank is good for many years of use>

It appears to be like most tanks that

have a wooden/particle board stand and hood to match.

Cindy

<Thank you for sharing. Bob Fenner>

Re: Acrylic tank crazing in seams – 5/22/12

Thanks - didn't notice my typos until I read this back - sorry.

Cindy

<Welcome; no worries. BobF>

|

|

|

Large Acrylic Aquarium Seams- Did I Buy A Problem?

2/13/12

Hi, we recently bought a large (300+ gallon) acrylic 1 inch thick

aquarium with center back overflow and nice steel stand. It has a

black acrylic back, is a nice deep shape, is 30" tall and

was not super cheap and is a hard to find shape (would not feel

happy throwing it away or putting a free sign on it). I just

noticed that some of the seams are not clear.

<I see this/these>

Many are but quite a few are not. The previous craigslist owner

said it did not leak at all. We have not filled it with water yet

because I wanted your feedback first. We looked for pictures that

looked like ours with what to do but did not find much, so am

sending the email.

I'm attaching pics for your feedback.

To describe the pictures I attached: Many Seams- quite a few look

like this Middle Left- towards the bottom of the picture shows a

whiter area of the seam Middle Left 2- shows the same area in the

back left of the photo Middle Left 3- close up of the same area

Top Seam- is a picture of an area of the top seam

What is your thought?

<I'd install square doweling (solvented) in all inside

seams. Read here re:

http://www.wetwebmedia.com/acraqleaks.htm

And if repair is needed where is good in southern California (we

are not capable ourselves) and is it worth it?

<See the "Yellow Pages" (analog and/or electronic)

re Plexiglas/Acrylic... you'll find sellers of tools and

materials, and fabricators... contact them re this repair if you

don't want to attempt it by yourself... IF you know and trust

a competent retailer (petfish) that does such repairs, ask them

re>

And your website it a great service, we've used it before for

research.

Thanks, Worried in So Cal

<Cheers, Bob Fenner, in not-so-sunny San Diego>

|

|

Clarity Plus Lifetime Warranty? (and acrylic tank

resurfacing/repair) -- 01/07/12

Hello,

<<Hey Garrett>>

I have recently purchased a 300 gallon acrylic aquarium from c-list for

a couple bucks and thought I was getting a real deal.

<<Mmm, is often the case'¦till one sees the scratches.

But even so, this can still be a 'deal' if you're willing

to apply some elbow-grease. Returning the tank's clarity is not all

that difficult>>

and I may have if I don't count for my labor resurfacing the

tank.

<<Ah!...yes>>

My question is and it's a three part'er; how would one go about

contacting the aquarium manufacturer being Clarity Plus (SeaClear, the

Casco Group and so on) to attempt to cash in on said warranty?

<<If this tank has been modified or repaired (other than

authorized) in any way, it's likely the warranty has been

voided>>

I cannot find any contact info for them anywhere. Wondering if maybe

they shut their doors?

<<Hard to say'¦their products seem to still be on offer

though. You might try contacting a retailer selling their product, such

as FishTanksDirect.Com>>

Second question:

Assuming I am not lucky enough to cash in on that warranty and continue

doing the work myself, how clear is clear enough for acrylic?

<<'¦? You would be surprised at what

'disappears' when water is added to the

tank>>>>

I have dry sanded from 120grit up to 400grit and then wet sanded from

400-4000grit and come back with polishing compound and have gotten it

very clear.

<<This is likely sufficient'¦adding water will

tell>>

However there still appears to be distortion from a few feet away.

<<Mmm'¦ This is from not sanding 'evenly' across

the entire surface of the panel'¦or at the least

'feathering out' the perimeter of the sanded areas. Failing to

do so creates what is called a 'lensing effect' and results in

the distortion you are now seeing>>

I can place a book inside and still read it but can't read it

looking through both panels (just a test for clarity no intentions of

reading underwater).

<<Indeed'¦kind of like trying to read through two

stacked glasses lenses>>

Is the distortion because I boogered-up the restoration process on the

acrylic

<<A likely scenario>>

or because the tank has some age and permanent-bowing to it?

<<A less likely scenario>>

Am I worrying to much and water will fix it?

<<Possibly'¦I would test and see'¦is possible

the lensing effect is not that noticeable/within acceptable viewing

limits>>

(have not finished the resurface part yet to retest clarity with water,

but don't want to waste my time if its going to look like poop)

Third question:

The seams of the tank in various places around the tank have turned

whitish in some spots. Almost like there is frost or ice between the

panels. None are very large maybe 2' at the most , but they do span

the whole 1/2' of acrylic. Never owning an acrylic tank I don't

know the risks involved.

<<Minimal'¦but again'¦a water

test'¦>>

It would be my assumption that the chemical bond broke there just

isn't leaking (have done a 2 week leak test with litmus paper on

the seams to verify leaks).

<<Then you likely don't have a worry re'¦but while

the tank is empty and dry you can easily beef-up these inside corners

with triangular acrylic doweling>>

Do these need to be shored up with the square braces as suggested in

other posts or can I take a needle with solvent and forces it in the

joint? Or something along those line?

<<My choice would be the acrylic doweling'¦applied very

carefully; to avoid any further marring of the viewing surfaces, with a

'thickened' acrylic solvent like Weld-On #16 or Craftics

#33>>

Any and all answers and suggestion will be greatly appreciated.

<<I hope I have served>>

Thanks,

Garrett Crance

<<Happy to share'¦ Eric Russell>>

acrylic tank, imperfections in joints

12/16/11

hi, huge fan of this web site, essential reading for fish keepers.

Think I've got a problem i need advice on, just purchased an

acrylic tank 48"Lx18"wx26"h. its made with cell cast

12mm acrylic. On inspection i noticed lots of small 1/2mm

bubbles on seam. there mainly on external edges but not just a

couple. I've spoken to the producer and he's said its normal

and wont effect strength much but I'm concerned about filling it

and will the life expectancy be reduced?

<Mmm, you're likely okay here in the short and long haul. The

quality may be a bit less, but this tanks should still function for

decades. Bob Fenner>

Re: acrylic tank 12/16/11

thanks for speedy reply Bob, will fill it tomorrow and hope for best.

Would siliconed external angle beads add any strength

<Almost none. Not worthwhile>

or am i better off leaving be so i can keep an eye for whitening or

crazing on these bubbles. thanks again.

<Welcome. I strongly doubt you will have problems w/ these seams.

Cheers, BobF>

180g acrylic tank... cloudy seams concern

10/28/11

Hello,

<Douglas>

I am finally getting around to setting up my 180g Clarity Plus

aquarium.

I have had the tank full for the past week doing a "leak

test" prior to putting in my living room without any signs of

leaks.

<Good and good>

I inspected the seams, and I think they look ok and fairly clear

however on the vertical front seams (where the front & side panels

join) there are some cloudy / bubble like imperfections, almost looks

like frost on a windshield? The spots don't run across the width of

the seam itself, and there was no evidence of a "whiteout"

cloudy area across the entire seam. The imperfections are more

prevalent on the outside edge of the seam, but is difficult to tell how

far the extend across the seam - perhaps 1/2 way in 2 small spots but

in most spots they look to < 1/4 of the way across the seam.

I didn't notice the spots getting worse over the week the tank was

filled.

I tried to take a photo, but given the way the front panel is rounded

off as it meets the corner it was difficult to get a good picture.

Obviously with a 180g tank the last thing I want is a leak in my living

room, from your experience working with acrylic is this normal and what

is the risk of separation that would cause a leak?

<Some small risk>

As a precaution do you

think I should have the inside seams of the tank reinforced with

1/2" acrylic square tube by a local plastics shop?

<Up to you... for the long term; yes>

Thanks again for your time & help

Doug

<Glad to share. Bob Fenner>

Re: 180g acrylic tank 10/28/11

Hello-

<Hi there again>

I mistakenly added my phone number at the bottom of the last email I

sent you, please delete if you decide to post it thank you!

<Oh yes; I mean no... We don't retain or reproduce folks'

contact info. w/o their express consent/urging. Cheers, BobF>

Doug

poor seam 6/5/2011

Hello; I have a 600 gal saltwater tank. One seam on a

1" X 1" acrylic 3' high corner has a

cloudy look half way up. .The rest of the seam is

still clear as well as all other corners. The tank is a 2 year old

reef-fish with many critters so emptying it would, I'm afraid, kill

some of my friends although I will if there is no other solution.

<There is none>

I was thinking of welding a strap down the seam

<This IS what I'd do... in ALL the inside seams... square

acrylic doweling is available... Solvent this in place with flat sides

to the two edges>

but then to make it look uniform I would have to do the same to the

other corners.

<Yes... Again, best to do now for ALL inside seams/corners>

The corners have a 3/4" radius so I don't think I could wrap

around the corner and get a good weld.

<INSIDE, not out>

(also I don't have the knowledge to heat the acrylic to bend it

)

<Just measure carefully and cut to abut>

The tank is very odd shaped ( like looking down on an H with a tub in

one end of the H and a shower on the other with the aquarium as the

walls ) plus there are straps welded across the top tying each side of

the H together. What I'm wondering is there a way to mend that seam

without emptying the water or any other solution?

<No; not>

Does the #40 epoxy weld under water?

<No>

Dan

<Good luck w/ your project. If it were, mine, I'd get some

experienced help. Bob Fenner>

240 g acrylic repair question -- 10/19/10

I've got a 240 g acrylic tank that I just filled with water for the

first time and when halfway filled I noticed @ 0.5 ml of water on

inside corner bottom panel seam of internal overflow box. Can I just

silicone it from

the inside of box? It doesn't leak to outside of aquarium just to

inside of rear corner overflow.

<You can try this... Silastic doesn't stick well to acrylic...

but if it/this is only a pin-hole leak w/ little pressure... this fix

might work.

Do make sure the surface is completely dry and clean ahead of applying

the Silicone. Bob Fenner>

135 gallon Clear for Life acrylic aquarium, seam-dowel

repair/strengthening 3/16/10

Hello everyone!

I have a problem or worry about a future problem. I bought a 135 gallon

Clear For Life acrylic tank about 4 years ago. the typical 72x24x18 at

3/8" to cut cost tank. It was setup fresh for a few years and when

I moved I never set it up. Well I decided to setup a ray/shark tank,

until they outgrow it. When I got all of my other equipment together, I

filled it, and after the system was running for a minute (literally a

minute) the rear right seam blew and flooded my living room.

<Yeeikes!>

I got about half of the water out into my yard instead of my carpet.

After contacting advanced aqua tanks they repaired that seam by adding

a corner brace at the bottom and up the side.

<Yes. A/the common approach/repair>

I brought it home and filled it with fresh and it held. It did the

usually bowing but I am seriously concerned about it happening again. I

have read pages and pages about acrylic tanks and I can tell you that

it does not have that much crazing as my 125 Uniquarium(which is a

whole other problem). My

ultimate question is about using weld-on or a similar product to

strengthen the seams before I set it up.

<?... only to anneal more corner doweling...>

I read one of the last questions, Re: Acrylic Tank Crack

Repair/Drilling Acrylic -- 12/31/07, that someone recommended it that

maybe it would apply to my situation as well. I don't want to do

something that could weaken an already weak joint.

<It would to only add it to an existing/old bond>

Also, if you do recommend it, after it has cycled transfer my

inhabitants of my other tank to and do the same to the Uniquarium. As I

mentioned it is a lot worse off where the crazing goes completely to

the interior of the back panel of the sump area.

<I would NOT simply apply solvent to a crazed area... DO look into

sealing square acrylic rod, cut to size, in the inside joints>

I have other questions about the sump setup and return of the 135 but

until I read those articles I will leave them alone.

Thank you for your time.

James B

<Do "chat" w/ others who have done this

modification/addition... perhaps have them help you one on one. Bob

Fenner>

Re: 135 gallon Clear for Life acrylic aquarium, leak

repair f' 3/17/10

Thanks for the direction! I contacted a local Plastics store and they

carry Weld-On and will cut pieces to fit the interior dimensions to

Weld-On to. No pun intended. In the corner where the overflow is, would

I want to adhere the joints that are in direct contact with the

water(the show side) or opposite?

<All inside joints>

Would it be wise to do this to the bottom joints as well, while I am at

it?

<Yes>

In the end I want to jump to a 180 Hex

<Unsuitable shape and volume>

for the shark and rays but until then, I'm stuck.

James B

<BobF>

Re: 135 gallon Clear for Life acrylic aquarium...

repair and system for Chondrichthyans -- 03/20/10

Thanks for the direction! I contacted a local Plastics store and they

carry Weld-On and will cut pieces to fit the interior dimensions to

Weld-On to. No pun intended. In the corner where the overflow is, would

I want to adhere the joints that are in direct contact with the water

(the show side) or opposite?

<... all inside joints need to be done>

Would it be wise to do this to the bottom joints as well, while I am at

it? In the end I want to jump to a 180 Hex for the shark and rays but

until then, I'm stuck.

James B

<You sent this before... A hexagon shaped system of this volume will

not work for these fishes. BobF>

Acrylic Tank Repair Question -- 12/14/09

Hi,

<<Hello>>

I recently purchased a 4ftx2ftx2ft ½' thick acrylic

aquarium. It was made by a local who claimed it was leak proof.

<<I'm sensing this is not the case'¦>>

Well I took it home and it leaks around the bottom in one of the

corners and about 6-8' along one side bottom seam.

<<Uh-oh'¦sounds like reason enough to return it to

me>>

I can also see a lot of little bubbles in the seams. As well he

didn't square up the tank perfectly and one of the sides sits out

1/6' off the bottom sheet. I am wondering if I should try to use

some Weldon 16 and go over all the seams or if I should just get rid of

this and find another?? It is brand new but leaks!!!

<<If the joints have been well enough assembled originally to

keep this tank from simply bursting apart when filled, you can likely

salvage it by solvent-gluing some angular acrylic rod along the seams

(there is such made for this type application, see the Net re). I would

suggest not trying to 'spot-fix,' but rather, glue the

filler-rod along the entire inside bottom perimeter.

Although'¦being a new purchase, why not return it for a

refund/replacement?>>

Thanks,

Matt Thomas Utah

<<Happy to share'¦ Eric Russell SC>>

Livestock Acrylic Tank Leaking 10/2/09

Hey Crew. I have an acrylic tank that is holding livestock that is

leaking. I've been reading through the site and only see

suggestions on sealing leaky tanks when they're dry. Is there a

solution to seal an acrylic tank when it has water in it?

Thanks!

Ryan Mullinax

<Not really Ryan... Some "not real" repairs can be made

short term... wedging a piece of flush square stock (rod) into the area

of the seam leak... with Silastic... but really... the tank needs to be

dried, resolvented. BobF>

Re: Livestock Acrylic Tank Leaking

10/2/09

Ok, thank you Bob. I really appreciate the knowledge and experience

that WWM provides the aquatic community. It has benefited me greatly

over the years.

<Ahh! Am very glad for this. Cheers, BobF>

1" thick acrylic - Can we fix it? 9/27/05 Hello, I

couldn't find a similar problem to mine except ...leak leak...

leak. I have a very large 500+ gallon tank. It's 1" baked

acrylic on all sides. I have saltwater in it and have had it for like 6

- 7 years. It's completely built in to a wall and is supported on a

steel structure. We noticed some water damage on a piece of quarter

round that was trimming it and when we removed the trim water started

spurting from a pin hole leak. The trim was actually holding it in

check some what. I don't want to try and remove the whole tank from

it's location as it will cost major in carpentry. Will this acrylic

cement (northcoastmarines) work for this type of leak? How does this

type of thing happen after all these years? Kim <This tank can

likely be repaired... in place. Do look into square

"doweling" (this is sometimes only flush/ninety degrees on

two of the four sides... You must make sure the flush sides are affixed

to the corners. What needs to be done? Drain, clean the tank entirely,

cut the doweling to size to fit in all corners (yes, including the

sides), and solvent in... The extra bit of acrylic in the corners

won't be obvious in time. Cheers, Bob Fenner>

Re: 1" thick acrylic - Can we fix it? 9/30/05

Thanks so much but where does one find square acrylic (I assume not

just plastic?) "doweling"? Kim <Should be available, as

well as solvent/Weld-on and cleaner from a large/r plastics distributor

in your town... or mail-order... Use your "Yellow Page"

directory, the Net to find. Bob Fenner>

Cracked acrylic tank 9/20/05 Well Bob, You were right,

only give it time....I've got a new one for ya. My crew and I were

installing a new 36" x 30" x 36" acrylic tank from AAT

today. As the tank was being set down on the floor, one of them lost

their grip for fear of getting their fingers pinched. The right front

corner of the tank hit the bare concrete floor from about 2 inches

up....that's when I heard that unquestionable cracking sound. I saw

my profits disappear before my very eyes. However, upon inspection, it

wasn't nearly as bad as I thought. The crack is actually in the

bottom plate about 1/4" in just beneath where the front panel

(front and sides are one piece with bent corners) is welded to the

bottom panel, about 6 inches from the start of the right corner radius.

This crack extends from the bottom surface upwards about 3/4" in

an arching pattern, almost like a rainbow...but not nearly as pretty,

and finishes back at the bottom surface. Its a pretty clean crack and

does not go anywhere near where there would be water. I figured that

because it directly underneath the front panel, that even if it extends

further over time, it would eventually dead end into the front panel

and because its almost dead center under the front panel, that there

would be plenty of material to keep it from leaking. Your thoughts on

this ???? Scott C. Wirtz >>>Greetings! Sorry it took so long

to get back to you, things are crazy for many of us here on the

"crew" and tons of queries coming in. Bottom line, it's

impossible for any of us to say for sure about your tank. I had a

similar thing happen though to a 300 gallon tank, and it was just fine.

Good luck! Jim<<< <<RMF would still run a bit of Weld-On

(of lower viscosity) into the cracked area>>

Need advice on

separating acrylic sheets... 8/27/05 Hi Bob, <Ed> My name is

Ed Ruiz. I'm in SLC, Utah. Seeing your vast experience in the hobby

and working with acrylic I hope I can get some advice from you. <I

see> I recently acquired a lot of 1/8 and 1/4" acrylic sheets

(24"x48") that had apparently been stored under less than

ideal conditions. I find that the sheets are still with their paper

masking on, but between each two sheets there is a yellow or blue

textile material that is holding them together. My theory is that they

were heavily stacked (too many sheets atop each other for a long period

of time - <In the heat...> I got them for free) and the masking

textile's adherent has bonded rather strongly. I have not

insistently attempted to separate the sheets and would like your

opinion, advice or suggestions. I will use the sheets to build

aquariums for a hatchery project I am working on. Ed Ruiz <Very hard

to separate... inserting long, thin metal strips between and prizing

apart is likely your only option... though this will very likely

scratch through the protective masking... Have you tried speaking with

folks in the acrylic business? Manufacturers of such do have

websites... I would get their input before proceeding. Bob

Fenner>

Re: need advice on separating acrylic sheets... 8/30/05

Thanks a lot Bob, your suggestion is exactly my wife's' and

makes sense. <Ahh, good company> As to the acrylic

manufacturer's or vendor's websites, they're more

interested in selling me a product for taking the paper masking off.

This tells me they did not pay much attention to my enquiry in the

first place. I'll go with your advice. Ed <Please make it known

how this goes... Years back I tried to do this... with piano wire and a

strong friends co-help, jamming thin metal strips twixt the sheets...

and getting the old masking off... what a lot of work besides! I would

listen to the acrylic manufacturer's, distributor's advice re

this. Bob Fenner>

Acrylic crack repair, opportunistic/typical

Moray behavior 11/11/05 I just bought a used 55 gal hexagon acrylic

tank. I was moving it around trying to determine placement when I

realized there is a crack in the top panel. No point in finding blame

now, I just want to know if I can save it or take this as a loss.

<Mmm, can likely effect a simple repair here> The crack,

definitely not crazing since I can feel a separation, starts from a

corner round of the large cutout and extends about 3 inch toward one of

the six sides. One more inch and it is going to hit the side edge!

I've been reading about using Weld-On and applying an acrylic panel

to the crack. <Yes> Also is drilling a hole at the end of the

crack going to stop it? <Not likely useful, necessary> Can I get

Weld-On at Home Depot if I were to try this? <Best to seek out from

a "Plastics" supply... look in your local Business Yellow

Pages Directory re> Should I worry about this crack since it is only

on the top panel? <Mmm, not much to worry about, but I would solvent

it closed> The tank is a standard 55 gal hex 24x24x28. It's

funny how things go wrong and just seem to spiral even more. I bought

the tank intending to make it a new home for my white-mouth eel about

15in, who has managed to eaten two smaller fish. Well he attacked and

ate my 6-7 inch lunare wrasse last night. I couldn't believe he was

able to swallow the wrasse or even catch it. What a sight! Thanks

<Welcome... an easy project/fix... Bob Fenner>

Repairing acrylic leaker 3/7/06 Hello, We are searching

for someone who can fix the leak in the seam of our large (8'W x

4'H x 2"D) acrylic salt water tank. <<Eeek!! A difficult

challenge at the least!>> The owner has said that he sign a

waiver that relieves the repair person of responsibility if the repair

does not hold. <<While there are several ways that this can be

repaired, no sane repair person will guarantee this work. The best

looking and safest repair will require emptying the tank, cleaning out

the defect and filling the void with a two part polymerizing adhesive.

A cheap and aesthetically non-pleasing repair could be made by gluing

an acrylic splint inside the defect with two-part or solvent adhesive

after cleaning the area with sandpaper. >> The leak is small and

is coming from the front left seam, about half way up the tank. The

tank currently is filled to below this level and still has fish in it.

Can you recommend anyone that could take this sort of job on? Regards,

Jennifer Ferguson, Woodwork Creations <<I don't know of

anyone to recommend. Beware that any repair does not address why this

occurred in the first place... was the tank properly built to begin

with? Is catastrophic failure imminent? Was the stand out of level?

Personally, I would strongly consider replacing the tank with one built

by a reputable builder. Best Regards. AdamC.>>

Leaking Acrylic Sump...Silicone Not the Answer -

12/12/06 Hi and thank you all for your support and knowledge.

<<Hello...is our privilege to share>> I have had my reef

tank for over a year now with good success. I am attempting to build a

custom-size sump inside the stand of my 125 gallon running reef. I

purchased the 3/8" acrylic and had it cut to size so the fit seems

to be good. I used Weldon-3 in all of the seams. I then let it dry and

used Weldon-16 to form a bead around the seams. <<Hmm,

shouldn't be necessary if the pieces are bonded correctly with the

Weldon-3, but won't hurt either. If you really want to

"strengthen" the corners/seams, you could cement in

triangular shaped corner braces (these are offered/can be found

"pre-made" on the Net)>> I filled the sump with

½-inch of water and the water leaks out of the seams.

<<Mmm, perhaps the "fit" was not as good as you

perceived. For the Weldon-3 to work properly the joints must fit

precisely to allow the cement to be drawn-in by capillary

action>> I tried to put another heavy coat of Weld-on-16 and let

it dry overnight. This also leaked. <<Hmm...just spreading it

over the surface isn't likely to help as you've discovered, but

if you can "force" this thicker bodied cement in to the